|

Jiaxing Furuisen Spunlaced Non-Wovens Fabrics Co., Ltd.

|

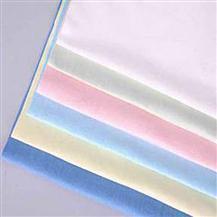

Spunlaced Non woven Fabric

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The non-woven fabric-like material step by long fibers, chemical, mechanical, heat or solvent treatment bonded together

Spunlace nonwoven process uses hydro-entanglement for bonding staple fibers; it involves mechanical intertwining of fibers by water jets. As a result, nonwoven fabrics made by this method have specific properties, as soft handle and drapability.

Most commonly, precursors are mixtures of cellulose and man-made fibers like Rayon (Viscose), Polyester and their blends.

Spunlaced fabrics show high drape, softness and comfortable handle because more fiber entanglement leads to increased strength without an increase in shear modulus.

Hydro entanglement is considered to be a highly versatile process because it can be used to produce nonwovens with a broad range of end-use properties.

Spunlaced fabrics show high drape, softness and comfortable handle because more fiber entanglement leads to increased strength without an increase in shear modulus.

Hydro entanglement is considered to be a highly versatile process because it can be used to produce nonwovens with a broad range of end-use properties.

Spunlace fabrics can be further finished, usually

dyed and/or printed, treated with binders to allow for wash durability, or fire retardants can be applied to resist burning. The fabric can be treated by antimicrobial agents to enhance resistance against microorganisms.

dyed and/or printed, treated with binders to allow for wash durability, or fire retardants can be applied to resist burning. The fabric can be treated by antimicrobial agents to enhance resistance against microorganisms.

Spunlaced fabrics spans from surgical packs and gowns, protective clothing as chemical barriers to wipes, towels and sponges for industrial, medical, food service and consumer applications. The main reasons for wide use of these fabrics in medical applications is based on relatively high absorption abilities. Another important criterion is absence of a binder in the fabric allowing sterilization of the fabric at high temperatures.

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Non Woven Fabric

Fabric Non Woven

Non Woven Fabric Bag

Pp Non Woven Fabric

Metallic Non Woven Fabric

Laminated Non Woven Fabric

More>>

.jpg)

.jpg)

.jpg)